Quality keep an eye on has forever hinged on one issue: trusting your measurements. If your dimensions are off, all the pieces downstream wobbles. In Dallas and across North Texas, where development schedules are tight and production timelines move at a dash, teams have leaned into three-D laser scanning to show guesswork into geometry. A good-run test collapses weeks of remodel into hours of verification. It does now not simply seize disorders, it ameliorations how teams place confidence in match, tolerance, and possibility.

I have worked on projects where that shift become evident. A fabricator in Irving sliced two weeks off a mezzanine set up via aligning steel to a test, not chalk lines. A hospital preservation near Medical District switched from tape and clipboard to a point cloud style, then stumbled on 28 conflicts between new ductwork and current piping previously a unmarried hanger went up. Those wins aren't magic, they may be the effect of disciplined container catch, properly-based datasets, and good comparisons against layout purpose.

This article specializes in what 3D Laser Scanning Dallas essentially means at the floor, in which it strengthens exceptional control, and wherein the limits nevertheless count number. If you might be choosing a 3D Laser Scanning Service Dallas or construction your own program, the right questions and workflows can pay off automatically.

What a test surely captures

A 3-D laser scanner measures hundreds of thousands of elements in keeping with 2nd, because of time-of-flight or segment-shift measurements to map surfaces. Each scan produces a factor cloud, a dense constellation of XYZ aspects with depth or shade values. Stitch several scans jointly by means of registration, and you get a single coordinate-exact brand of the website online.

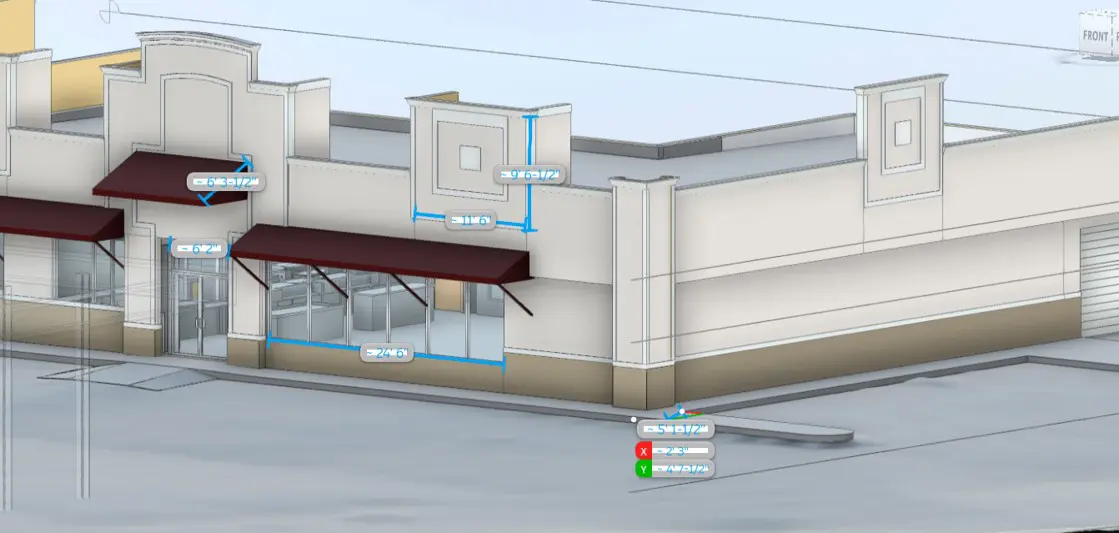

In practice, quality keep an eye on good points convey up in three approaches. First, as-constructed constancy: you already know the place matters are, not wherein drawings say they should always be. Second, comparative prognosis: protecting the aspect cloud with the layout model unearths deviations in truly numbers, which includes a beam sitting 1.25 inches low. Third, dimensional reporting: as opposed to spot checks with a tape measure, you may have complete-surface measurements that train traits and patterns, like flooring flatness drifting closer to the west part.

The tools things less than the workflow. A terrestrial scanner positioned at neatly-deliberate stations in most cases drives the very best accuracy for inside spaces. Mobile scanners and SLAM methods cover more floor swifter, treasured for big warehouses or retail fitouts, however with a customary hit on precision. Photogrammetry grants visual context and will probably be extremely good for texture on background tasks, nonetheless accuracy relies upon seriously on management. In Dallas, where summer warmness shimmers by lengthy warehouse corridors and steel roofs can bias readings, opting for the exact catch mode and time of day shall be the difference among a fresh registration and a troublesome remodel of the test itself.

Why Dallas initiatives see short ROI

North Texas production and production push challenging on schedules. Tilt-up distribution facilities turn over in a few months. Tenant improvements cycle due to in weeks. When the finish line is that shut, one missed interference can absorb your contingency. The intensity of coordination between MEP contractors and structural metal in healthcare, increased preparation, and info heart initiatives in Dallas magnifies the risk.

Cost force multiplies the beneficial properties from early detection. A mechanical clash stuck in a level cloud overlay prices a few hours to reroute earlier than fabrication. Find it after concrete, and you possibly paying for center drilling, sleeves, firestop, and a week of lost go with the flow. In improved manufacturing, a misaligned fixture found out using scanning can keep an entire batch run, exceedingly in aerospace, in which Dallas has a deep give chain and tight tolerance standards.

Local aspects play a role too. Many Dallas municipalities require suitable documentation for as-builts and closeout. Owners with portfolios spread throughout the Metroplex increasingly be expecting digital twins, no longer just PDFs in a turnover binder. A scan-subsidized fashion ticks the ones bins with authority.

What pleasant handle looks like with a aspect cloud

The strongest consequences manifest while scanning is woven into best making plans at the outset. Treat it like survey management, now not a novelty instrument. You resolve what subjects dimensionally, define tolerances, then tailor the experiment to clear up the ones tolerances.

For concrete, we most of the time plan scans after each one important pour. We measure slab flatness and levelness, confirm embeds, and look at various column line positions in opposition to manipulate. On one Fort Worth warehouse activity, scanning stuck two anchor bolt styles skewed by means of roughly 0.6 degrees. That is a minor misalignment on paper, but it'll have forced shim plates and misfit wall panels down the road. The metal contractor re-drilled templates earlier than transport, then sailed by using erection with fewer subject fixes.

For mechanical rooms, the sport is clearances and maintainability, not simply geometry. You can see regardless of whether a valve is accessible, whether or not a pump can be pulled, regardless of whether the code-required provider space is proper. Words on a submittal sheet are hardly ever as persuasive as a element cloud with colorized offsets exhibiting how shut you might be to the goal clearance.

When tolerances are tight, dimensioning turns into a rigor. Think in millimeters whenever you desire it, inches if you happen to do now not, but decide upon your models dependent on the resolution being made. Most exceptional decisions are living in a band, not a variety of. A curtain wall is delicate to plumbness and anchor spacing. A pipe rack is sensitive to deflection and offset. Scanning will become the neutral referee.

Accuracy, resolution, and the parable of perfection

Good scanners in skilled fingers can acquire sub-centimeter accuracy over meaningful distances. Still, no scan is preferrred. Figure out the accuracy you somewhat need and construct the capture to meet it, in place of chasing most density far and wide.

Accuracy is driven by dissimilar aspects: instrument specification, station spacing, registration method, environmental prerequisites, and regulate elements. Heat shimmer on asphalt, vibration from close by traffic, or reflective surfaces like stainless-steel can introduce noise. In a Dallas summer time, we quite often agenda external scans originally light to reduce thermal gradients and produce cleanser ambitions. Indoors, HVAC rumble https://www.yelp.com/biz/reality-imt-dallas and busy trades can nudge tripods. It does not take lots, a bumped scanner mid-rotation can compromise a station and ripple through registration.

Resolution is break free accuracy. You can experiment at high density and nevertheless be flawed in case your registration drifts. Conversely, a reduce-density test anchored to just right control should be would becould very well be extra faithful for dimensional calls. For clashes and structure, steadiness density with processing pace. Most teams find a sweet spot wherein wanted surfaces have excessive detail at the same time as background facts is lighter.

A trick that can pay: target structure with handle. Use spheres and checkerboards tied to surveyed features. This improves registration and traceability. Free cloud-to-cloud registration can work in monotonous spaces, yet it can be a chance in repetitive aisles the place same geometry confuses the algorithm. An experienced 3D Laser Scanning Service Dallas workforce will train you the control plan prematurely and clarify how the coordinate approach aligns along with your surveyor’s baseline.

From raw facets to selections that stick

Turning a factor cloud into value requires greater than a highly image. You desire a workflow that takes you from box trap, as a result of registration and cleanup, to deliverables that tie without delay into your caliber plan.

On known creation initiatives, the deliverables encompass a registered factor cloud in multiple codecs, a 360 photo walk for context, and a coordination variation where the element cloud sits along the existing BIM. I motivate teams to put up keep drawings that reference element cloud slices for vital dimensions. If a fabrication shop in Dallas is chopping stair stringers, a number of sectional views showing slab area positions from the test can prevent a misfit on installation day.

Comparisons to layout are the place perception emerges. Color maps are worthwhile, yet they will lie to if the tolerance bands are not nicely selected. If your slab tolerance facilitates plus or minus half an inch, then a heatmap that reds out at a quarter inch will indicate drama wherein none exists. On the opposite hand, if your sign-off calls for a quarter inch, then your map will have to replicate that rigor. The legend is simply not ornament, it truly is the agreement.

For manufacturing, Geometric Dimensioning and Tolerancing (GD&T) with test-dependent inspection is a helpful system. You digitize the half or fixture, then run inspection routines that ranking flatness, parallelism, situation, and profile opposed to nominal. The key lies in datum method. If you restore a less than perfect component to an idealized datum without awareness how it truly is restrained inside the true job, your metrics will probably be off. Good metrologists map datums to the absolutely fixturing formulation, then interpret outcomes with strategy competencies. A Dallas aerospace enterprise we labored with used this way to isolate a machining flow to a unmarried vise jaw, saving untold hours of blind troubleshooting.

Where a Dallas-extraordinary approach helps

Dallas spans dense urban infill, sprawling commercial parks, getting old midcentury campuses, and a flood of latest multifamily. Each atmosphere variations how and why you experiment.

Downtown infill rewards surgical precision. Tight alleys, delicate buddies, and morning visitors home windows pressure speedy setups and clear management. Quick evening scans after crews roll out can feed a morning coordination assembly with clean knowledge.

Industrial parks push scale. Imagine 1000000 rectangular toes of racking in a position to go are living in six weeks. A mobile mapping move validates aisle widths and clear heights, whereas excessive-accuracy stations determine critical parts like fire pump rooms and dock leveling pits. The trick is to combo tools with no perplexing your records lineage.

Healthcare tasks around the Medical District prize actuality over pace. Infection control, routing around are living methods, and as-developed irregularities from previous renovations make scanning each bit as extreme as plan evaluate. When we scanned an lively chiller plant, aligning shutdown windows with scanner positioning let us capture indispensable appliance from vantage elements that would be blocked as soon as systems restarted.

For infrastructure, take into accounts multi-disciplinary overlays. Scanning a brand new pale commercial spur close to current utilities? Pair laser scans with floor-penetrating radar archives within the equal coordinate machine. Even if the radar presentations probabilities rather then certainties, the spatial alignment with the scan facilitates planners weigh menace.

Common traps and how you can circumvent them

The mistakes I see repeat more typically than the unconventional issues. Most come from treating the scan as a unmarried magic step instead of a method.

One catch is scanning too past due. If you're scanning after steel is solely erected and puzzling over why your embeds neglected by an inch, the scan will make sure your anguish, no longer relieve it. Scan beforehand imperative installations, and plan look at various-ins at milestones that influence downstream paintings.

Another is inadequate policy. A scan that misses the bottom of apparatus or the go back plenum inside of a ceiling will look captivating and be functionally ineffective the place the clash hides. Walk your path with the similar rigor a photographer uses for assurance. Ask what surfaces remember, then guarantee that you would be able to see them from a minimum of two stations.

Registration drift masquerades as fact. If manage factors are weak or spacing is simply too extensive, the cloud is likely to be internally regular and nevertheless off absolute coordinates. That things when you employ the test for structure or examine against survey elements. Good exercise is to carry returned determine factors which can be measured independently, then report residuals actually.

Finally, the deliverables can sink you. A raw cloud dumped on a shared pressure without index, no viewpoints, and no orientation naming conference wastes everybody’s time. Curate it. Publish a ordinary navigation 3D Building Scanning Services guideline, a short screencast, or bookmarked stations. Reference a room numbering plan or grid machine persons already understand.

Choosing a 3-D Laser Scanning Service Dallas

If you might be evaluating services, pass the brochure gloss and dig for operational clarity. What you prefer to know is how the workforce reduces uncertainty and the way at once they translate area data into decisions your workforce can act on.

A wise way to frame the conversation:

- Ask for a pattern management plan and registration report, no longer simply snap shots. You would like to work out target counts, residuals, and the way they anchor to survey control. Clarify tolerances tied to use situations. A service may want to let you know where cell mapping suffices and the place tripod stations are non-negotiable. Review their deliverable specifications. Request a short demo of the way they reward issue overlays, cloud-to-sort deviations, and QA annotations. Confirm facts lineage and versioning. You desire self assurance that the cloud aligns with the current coordinate approach and the correct style edition. Talk approximately time table integrity. A service who can experiment at night and ship preliminary overlays by the subsequent afternoon will offer protection to your agenda far multiple who charges a reduce rate with a two-week turnaround.

Those aspects separate a pictures carrier from a measurement partner. In Dallas, with stacked trades and compressed periods, the latter is what you want.

Integrating scans into on a daily basis coordination

Scans do no longer dwell in a vacuum. On healthful projects, they feed the equal coordination loops that already exist.

Weekly conflict detection meetings was a ways extra effective after you walk the variation with the aspect cloud toggled on. You can prevent arguing approximately whose type is “properly.” The cloud breaks ties. Use kept views keyed to RFI numbers. When a superintendent asks regardless of whether a gap can shift six inches, you can actually pull up the cloud and instruct a fresh or congested path all of a sudden.

Field teams advantage from easy viewports more than anything. QR codes published in rooms that hyperlink to a selected station viewpoint can rework QA walks. A mission engineer can stand in which the scanner stood and ensure that frames suit the photo and measurements. No guesswork, no measurements ignored due to the fact that any one forgot the precise ladder.

On the fabrication edge, department shops running from factor-cloud-referenced submittals document fewer returns. We worked with a Dallas stair fabricator who used factor cloud sections to validate ground elevations and wall planes formerly slicing. It decreased his field weld time per run with the aid of approximately 30 %, a margin that outlasted that unmarried venture.

Case notes from the field

A statistics heart fitout in Garland had a hall dense with cable trays, fire mains, gasoline strains, and ductwork. The preliminary variety regarded sparkling, then the test confirmed the slab sagged 1 / 4 inch over 40 feet, enough to tilt tray supports into the course of a damper actuator. Re-leveling the supports early evaded a days-long transform. The test paid for itself in a single hall.

At a old theater upkeep close to Deep Ellum, scanning captured the exact curvature of plaster partitions and balcony edges. The millwork bundle obligatory that geometry to pre-fabricate panels that hugged the shape. If we had depended on archival drawings, the panels would have required widespread web page scribing. The experiment-to-CAD workflow produced templates that match on the first try out.

In a precision device shop, a lathe improve brought a subtle toolpath deviation. A hand-held laser tracker scanned a pattern side, and the deviation map confirmed an eccentricity that matched thermal enlargement during a selected spindle velocity diversity. Adjusting coolant float and heat-up collection resolved the illness. That repair depended on a experiment that could see traits over a full profile, not a handful of caliper checks.

Managing archives and retaining it sustainable

Point clouds get sizable speedy. A single day’s scanning can generate tens of gigabytes. Without area, you drown your group in archives. Establish a clean structure for storage, versioning, and archival. Name clouds by means of date, level, and grid. Lock baseline coordinate frames and rfile any ameliorations. Before publishing to a fashion coordination area, decimate non-indispensable areas and clip to rooms or stages, so users usually are not dragging the total mission once they desire one room.

Think approximately toughness. Owners progressively more want usable as-builts post-occupancy. Deliver in codecs so that you can open five years from now. Store a impartial layout like E57 along proprietary codecs. Include a readme that explains coordinates, instruments, and orientation. Put your registration report in the equal folder. It is really good what number complications that small act prevents.

Security issues too. Some facilities in Dallas, distinctly info facilities and protection-adjoining manufacturers, have regulations on imagery and placement facts. Work with IT to comfy garage and management exterior sharing. Watermark pix if required and document who has entry.

Budgeting with intelligence

Costs fluctuate primarily based on scope and desired accuracy. For straight forward architectural as-builts of a midsize workplace surface in Dallas, a experiment-to-cloud deliverable could run in the low five figures. If you need special MEP capture, tight tolerances, evening work, and a complete deviation diagnosis, predict greater. Mobile mapping can minimize seize can charge for mammoth open environments, but do now not be penny smart if the selection at hand demands tripod-grade accuracy.

The premier cost financial savings reveal up while the scanning plan targets determination elements. If a large component of your probability sits in a primary plant, spend the scanning attempt there. Capture beyond the fast want handiest in case you have a reputable downstream use case. Owners sometimes ask for every thing scanned “simply in case.” Push to come back with a purpose. Coverage must always mirror chance and worth, no longer curiosity.

Training your team to study the data

A test is simplest as constructive as the team’s talent to interpret it. Teach challenge engineers and superintendents how you can navigate viewers, degree distances, and confirm coordinates. Run brief workshops the place you compare a detail from the kind to the cloud and focus on discrepancies. Encourage natural skepticism. If the cloud and style diverge, anybody ought to ask regardless of whether registration slipped or the mannequin is outdated.

The habit to construct is last the loop. When a experiment reveals a conflict and individual worries an RFI or modifications a format, tag that occasion and the relevant view. Over time, these tagged views come to be a dwelling heritage of threat lowered. That visibility strengthens your case for scanning on a better mission with no resorting to summary ROI arguments.

Where the boundaries show

Laser scanning is strong, but it is absolutely not a panacea. Highly reflective or transparent surfaces would possibly scatter or take up the beam, yielding noisy or absent archives. Tightly packed overheads can disguise surfaces even at a couple of stations. If you desire to peer behind an object or inside a desktop, scanning can't bend easy round corners. Supplement with selective disassembly, borescopes, or basically greater time on structure.

Change administration is one more decrease. A scan is a snapshot. On quickly-relocating sites, the cloud a while immediately. If crews are shifting rapid, you want a cadence that helps to keep the cloud proper. Otherwise, any individual will say, not unfairly, that the test is “already old-fashioned,” and forget about it. Better a smaller, general test close principal work fronts than a sprawling seize that lands per week past due.

Finally, beware of over-trusting colorized imagery. Pretty snap shots seduce. Quality control lives inside the numbers, the regulate factors, the residuals, and the side-with the aid of-edge overlay with layout intent. Keep that field and you will steer clear of judgements centered on a photograph that simply seems to be true.

The Dallas merit while you get it right

Quality manage subsidized with the aid of three-D laser scanning elevates the craft and the business. It wins returned schedule, reduces RFIs, and shrinks punch lists. It supplies self belief to owners who wish fewer surprises and greater documentation. In Dallas, the marketplace rewards that reliability. Subs who come to coordination meetings with level-cloud evidence turn out to be the ones GCs call first. Owners who accept precise as-builts emerge as with diminish operating expenses and fewer headaches all the way through future renovations.

If you adopt scanning with cause, treat it as a dimension area, and elect a three-D Laser Scanning Service Dallas that stocks that approach, you may think the big difference. Fewer arguments about what exists. Fewer layout misses. More first-time matches. Quality turns into much less about firefighting and extra about orchestration, and that shift is as tangible as steel set to the right line.

The end result is discreet and uncommon: a team that trusts its dimensions. When that takes place, each and every resolution quickens, each and every handoff receives cleanser, and the paintings itself appears and performs the manner it used to be intended to. That is how quality handle should suppose, and three-D Laser Scanning Dallas presents you the means to get there.